ISO 9001 and EN 9100 certifications

The Groupe ABCM is certified ISO 9001 V2015 and EN 9100, two standards that guarantee rigorous quality management. ISO 9001 certification attests to the Group’s compliance with quality standards at every stage of its production process, promoting continuous improvement and customer satisfaction.

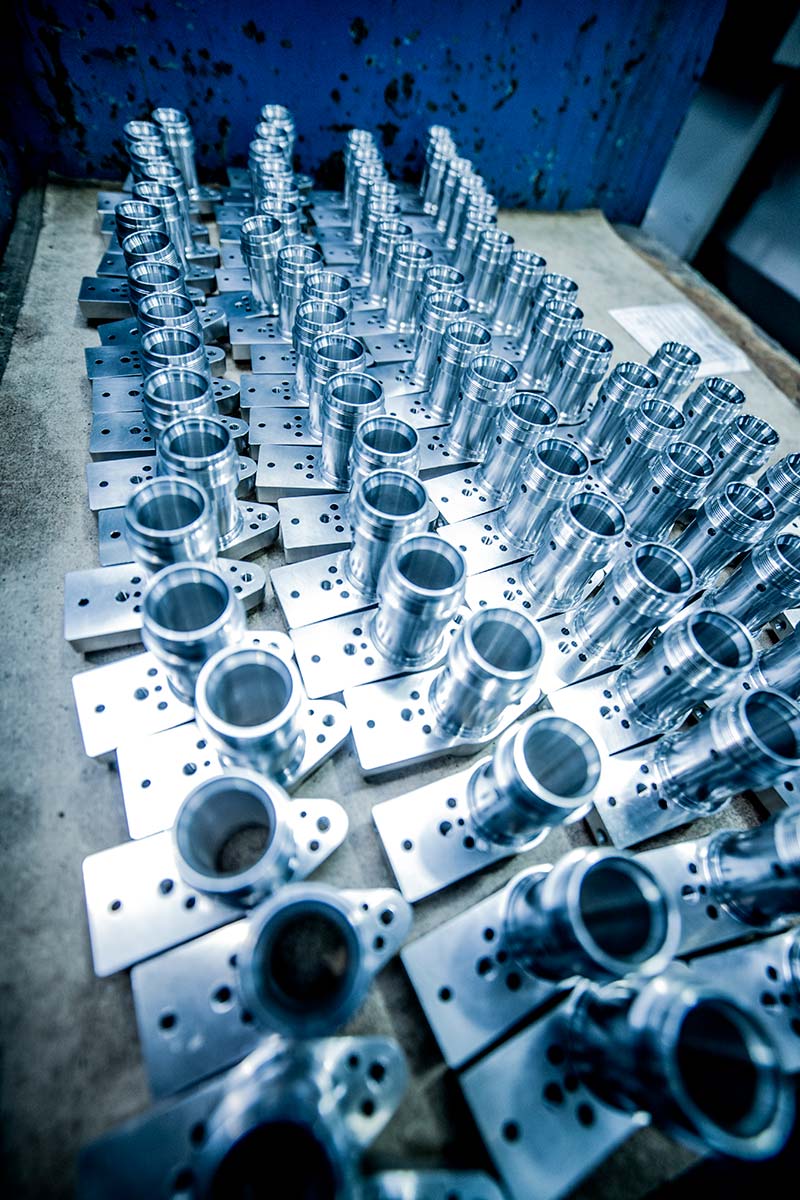

EN 9100 is specific to the aerospace and defense sectors. It is based on the requirements of ISO 9001, while reinforcing them to suit the specific features of these highly regulated industries. This certification testifies to our ability to meet the rigorous requirements of our customers in these sectors, by guaranteeing the safety, reliability and traceability of the parts we produce.

These certifications are complemented by specific qualifications for critical processes, regularly audited to ensure compliance and operational excellence (such as welding qualifications). Thanks to a structured organization and rigorous control procedures, we are able to detect and correct non-conformities at every stage of production, thereby ensuring greater responsiveness and continuous improvement of our processes.