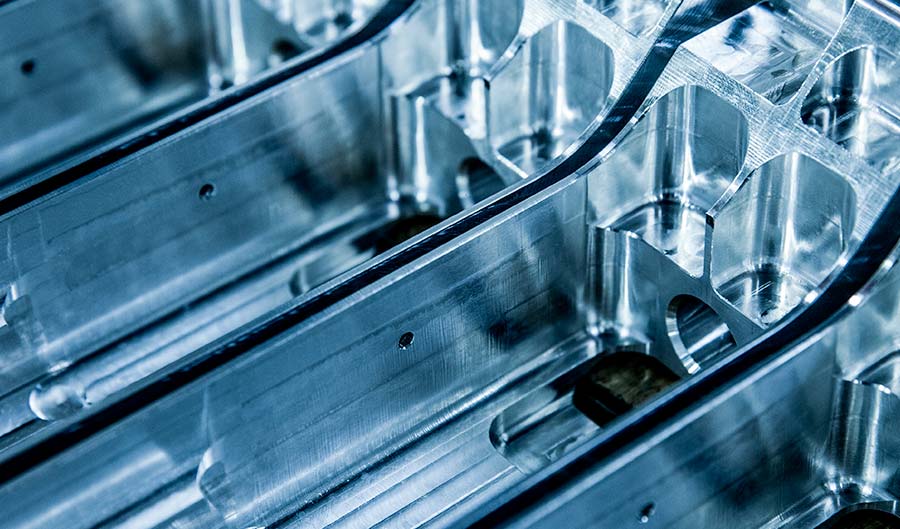

With more than 500,000 axles machined in 2024, the ABCM Group has established itself as a national player in the machining of articulation axles, essential components for the durability and performance of machines used in handling and public works. Our joint axles are manufactured to precise tolerances to ensure smooth movement and maximum strength under heavy loads.

Materials handling and public works equipment, such as forklift trucks, depend on the quality of these components to ensure safe and efficient operations. Thanks to our machining expertise, we are well equipped to produce articulated axles adapted to the most demanding working conditions, guaranteeing their long-term durability and reliability.

Customised manufacturing to meet the needs of the sector

Every project in the materials handling and public works sector presents unique challenges. That’s why the Groupe ABCM offers bespoke solutions, tailoring the manufacture of our articulated axles to the exact specifications of each customer. Our production capabilities mean that we can respond to specific requests, from small series for specialist applications to large series for large-scale production.

Our commitment to innovation means that we continually invest in the latest machining technologies. This not only enables us to improve the precision of our products, but also to optimize production processes for greater efficiency and lower costs.

Quality and reliability: fundamental values

Quality is at the core of all Groupe ABCM operations. We have implemented rigorous quality control processes to ensure that every articulated axle manufactured meets industry standards. Our teams of engineers and technicians oversee every stage of the production process.

By working with quality materials and using cutting edge machinery, we ensure that our articulated axles are built to resist even the toughest environments. These components are tested to withstand wear, heavy loads and extreme environmental conditions.