Tailor-made support for your projects

Every project is unique, and the Groupe ABCM is dedicated to providing customised solutions. From the study of your needs to the final implementation, we work closely with our customers to design tailor-made products.

Study and analysis of your project

The Groupe ABCM’s technical expertise comes into play right from the early stages of your rail projects. Our teams work closely with you to understand your needs, constraints and objectives. This essential phase enables us to suggest appropriate solutions and guarantee that our work complies with technical specifications and railway requirements.

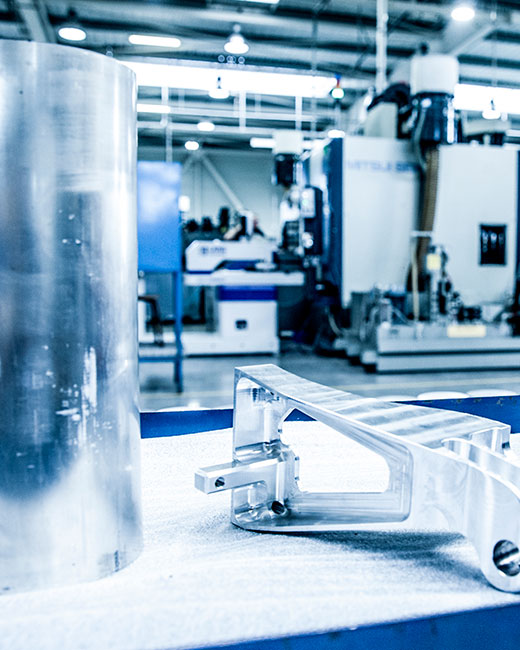

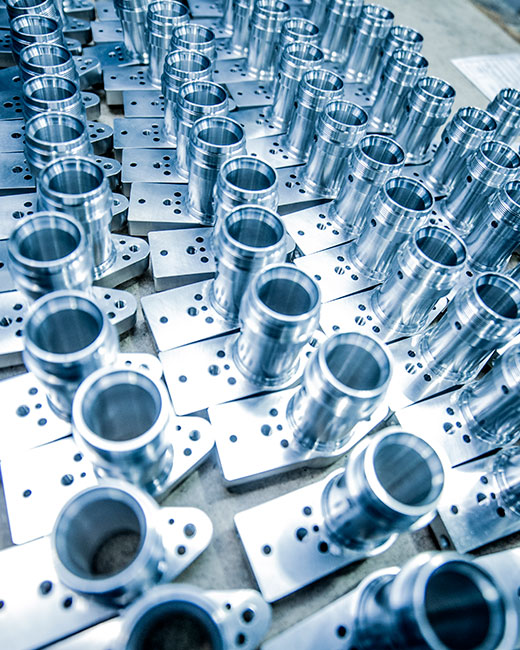

Prototyping: validating your concepts before production

The Groupe ABCM offers prototyping services that make it possible to manufacture test parts to validate their design, feasibility and performance before large-scale production. This approach guarantees controlled industrialisation and consistent quality during the series production phase.